USING SOME MATHEMATICAL MODELS IN

MODELING MUSHROOM DRYING (AGARICUS BISPORUS)

MODELING MUSHROOM DRYING (AGARICUS BISPORUS)

Abstract

In the present study, a thin-layer drying kinetics of Agaricus bisporus mushroom was experimentally investigated in convective dryer. Experiments were performed at air temperatures of 35There is an interest in information regarding the most suitable conditions for the different types mushrooms drying process. All the studies, experiments and analyzes performed by the authors are a basis for creating a Web-based platform with the help of which the most suitable drying model can be offered when specifying the mushrooms type and the drying parameters. The Web-based platform will be able to add new data and analyze it automatically which will allow the platform self-improvement.

Citation details of the article

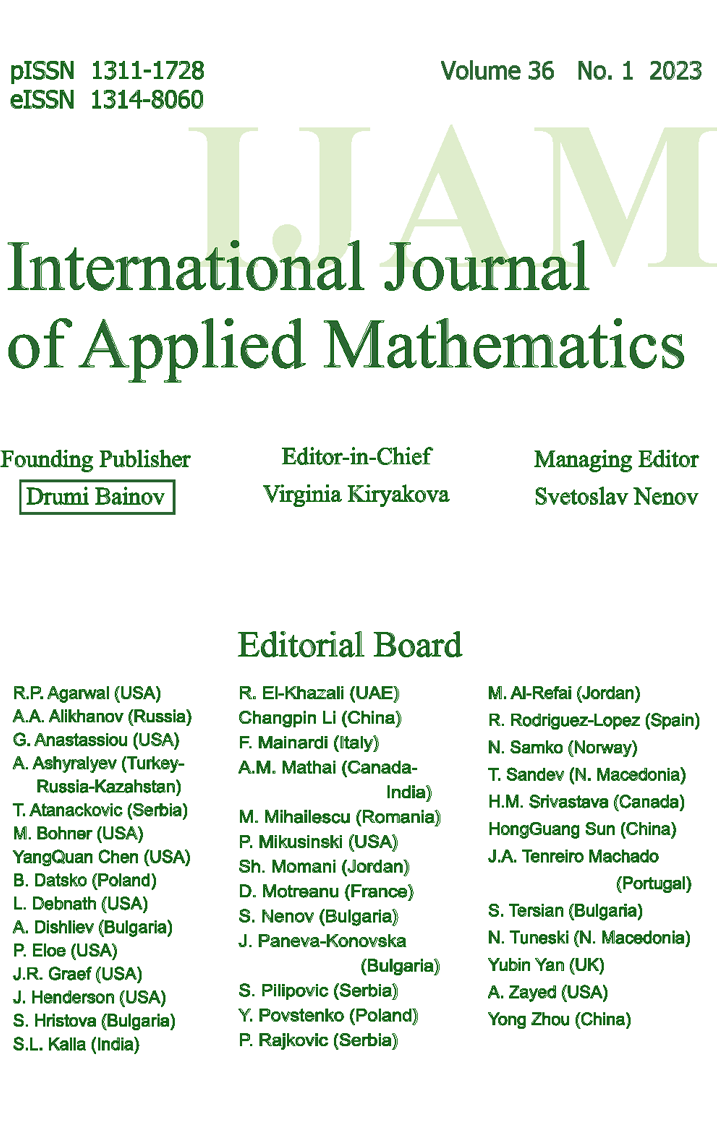

Journal: International Journal of Applied Mathematics Journal ISSN (Print): ISSN 1311-1728

Journal ISSN (Electronic): ISSN 1314-8060

Volume: 33 Issue: 1 Year: 2020 DOI: 10.12732/ijam.v33i1.9

Download Section

Download the full text of article from here.

You will need Adobe Acrobat reader. For more information and free download of the reader, please follow this link.

References

- [1] R. Alimohammadi, Assessing some estimation criteria of measurement error for categorical data, International Journal of Applied Mathematics, 30, No 2 (2017), 85-90; DOI: 10.12732/ijam.v30i2.1.

- [2] T. Arumuganathan, M. R. Manikantan, R. D. Rai, S. Anandakumar, V. Khare, Mathematical modeling of drying kinetics of milky mushroom in a fluidized bed dryer, International Agrophysics, 23 (2009), 1-7.

- [3] S.J. Babalis, E. Papanicolaou, N. Kyriakis, V.G. Belessiotis, Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficuscarica), Journal of Food Engineering, 75 (2006), 205-214.

- [4] M. Basunia, T. Abe, Thin layer solar drying characteristics of rough rice under natural convection, Journal of Food Engineering, 47 (2001), 295-301.

- [5] L.M. Diamante, P.A. Munro, Mathematical modeling of the thin layer solar drying of sweet potato slices, Solar Energy, 51 (1993), 271-276.

- [6] L. Dospatliev, M. Ivanova, Ordinary least squares linear regression model for estimation of Copper in wild edible mushrooms, Oxidation Communications, 42, No 2 (2019), 185-193.

- [7] L. Dospatliev, V. Lozanov, M. Ivanova, P. Papazov, P. Sugareva, Amino acids in edible wild mushroom from the Batak Mountain, Bulgaria, Bulgarian Chemical Communications, 51, No D (2019), 92-96.

- [8] İ. Doymaz, Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots, Biosystems Engineering, 89, No 3 (2004), 281-287.

- [9] İ. Doymaz, Effect of pre-treatment and air temperature on drying kinetics and quality of Jerusalem artichoke, Scientific Study & Research, Chemistry & Chemical Engineering, Biotechnology, Food Industry, 19, No 4 (2018), 395-409.

- [10] C. Ertekin, O. Yaldiz, Drying of eggplant and selection of a suitable thin layer drying model, Journal of Food Engineering, 63 (2004), 349-359.

- [11] R.K. Goyal, A.R.P. Kingsly, M.R. Manikantan, S.M. Ilyas, Mathematical modelling of thin layer drying kinetics of plum in a tunnel dryer, Journal of Food Engineering, 79 (2007), 176-180.

- [12] M. Ivanova, L. Dospatliev, Econometric model for estimation of heavy metals in wild edible mushroom (Suillus luteus), International Journal of Applied Mathematics, 32, No 4 (2019), 721-731; DOI: 10.12732/ijam.v32i4.11.

- [13] M. Ivanova, N. Katrandzhiev, L. Dospatliev, P. Papazov, Comparison of mathematical models for mushroom drying (Amanita caesarea), Journal of Chemical Technology and Metallurgy, 54, No 5 (2019), 920-925.

- [14] V.T. Karathanos, V.G. Belessiotis, Application of thin-layer equation to drying data of fresh and semi-dried fruits, Journal of Agricultural Engineering Research, 74 (1999), 355-361.

- [15] R.P. Kingsly, R.K. Goyal, M.R. Manikantan, S.M. Ilyas, Effects of pretreatments and drying air temperature on drying behaviour of peach slice, International Journal of Food Science and Technology, 42, No 1 (2007), 65-69.

- [16] G.L. Light, On the mean of sample-standard-deviation, International Journal of Applied Mathematics, 31, No 3 (2018), 359-370; DOI: 10.12732/ijam.v31i3.5.

- [17] A. Maskan, S. Kaya, M. Maskan, Hot air and sun drying of grape leather (pestil), Journal of Food Engineering, 54 (2002), 81-88.

- [18] J.R. Moss, L. Otten, A relationship between color development and moisture content during roasting of peanut, Canadian Institute of Food Science and Technology Journal, 22 (1989), 34-39.

- [19] A.S. Mujumdar, Mujumdar’s Practical Guide to Industrial Drying, Brossard, Quebec, Canada: Exergex Corporation (2000), 1-20.

- [20] J.R. O’Callaghan, D.J. Menzies, P.H. Bailey, Digital simulation of agricultural dryer performance, Journal of Agricultural Engineering Research, 16 (1971), 223-244.

- [21] Y.I. Sharaf-Eldeen, J.L. Blaisdell, M.Y. Hamdy, A model for ear corn drying, Transactions of the ASAE, 39 (1980), 1261-1265.

- [22] S. Suguna, M. Usha, V.V. Sreenarayanan, R. Raghupathy, L. Gothandapani, Dehydration of mushroom by sundrying, thin-layer drying, fluidized bed drying and solar cabinet drying, Journal of Food Science and Technology, 32 (1995), 284-288.

- [23] T.L. Thompson, R.M. Peart, G.H. Foster, Mathematical simulation of corn drying-a new model, Transactions of the ASAE, 11 (1968), 582-586.

- [24] Y. Tulek, Drying kinetics of oyster mushroom (Peurotus ostreatus) in a convective hot air dryer, Journal of Agricultural Science and Technology, 13 (2011), 655-664.

- [25] L. Tuley, Swell time for dehydrated vegetables, International Food Ingredients, 4 (1996), 23-27.

- [26] L.R. Verma, R.A. Bucklin, J.B. Endan, F.T. Wratten, Effects of drying air parameters on rice drying models, Transactions of the ASAE, 85 (1985), 296-301.

- [27] C.Y. Wang, R.P. Singh, A single layer drying equation for rough rice, American Society of Agricultural Engineers, MI, (1978), 108-115.

- [28] G. Xanthopoulos, Gr. Lambrinos, H. Manolopoulou, Evaluation of thinlayer models for mushroom (Agaricus bisporus) drying, Drying Technology, 25 (2007), 1471-1481.

- [29] O. Yaldiz, C. Ertekin, H.I. Uzun, Mathematical modeling of thin layer solar drying of sultana grapes, Energy, 26 (2001), 457-465.

- [30] N.P. Zogzas, Z.B. Maroulis, D. Marinos-Kouris, Moisture diffusivity data compilation in foodstuffs, Drying Technology, 14, No 10 (1996), 2225-2253.

- [31] S. Çelen, K. Kahveci, U. Akyol, A. Haksever, Drying behavior of cultured mushrooms, Journal of Food Processing and Preservation, 34 (2010), 2742.